October 26th, 2022

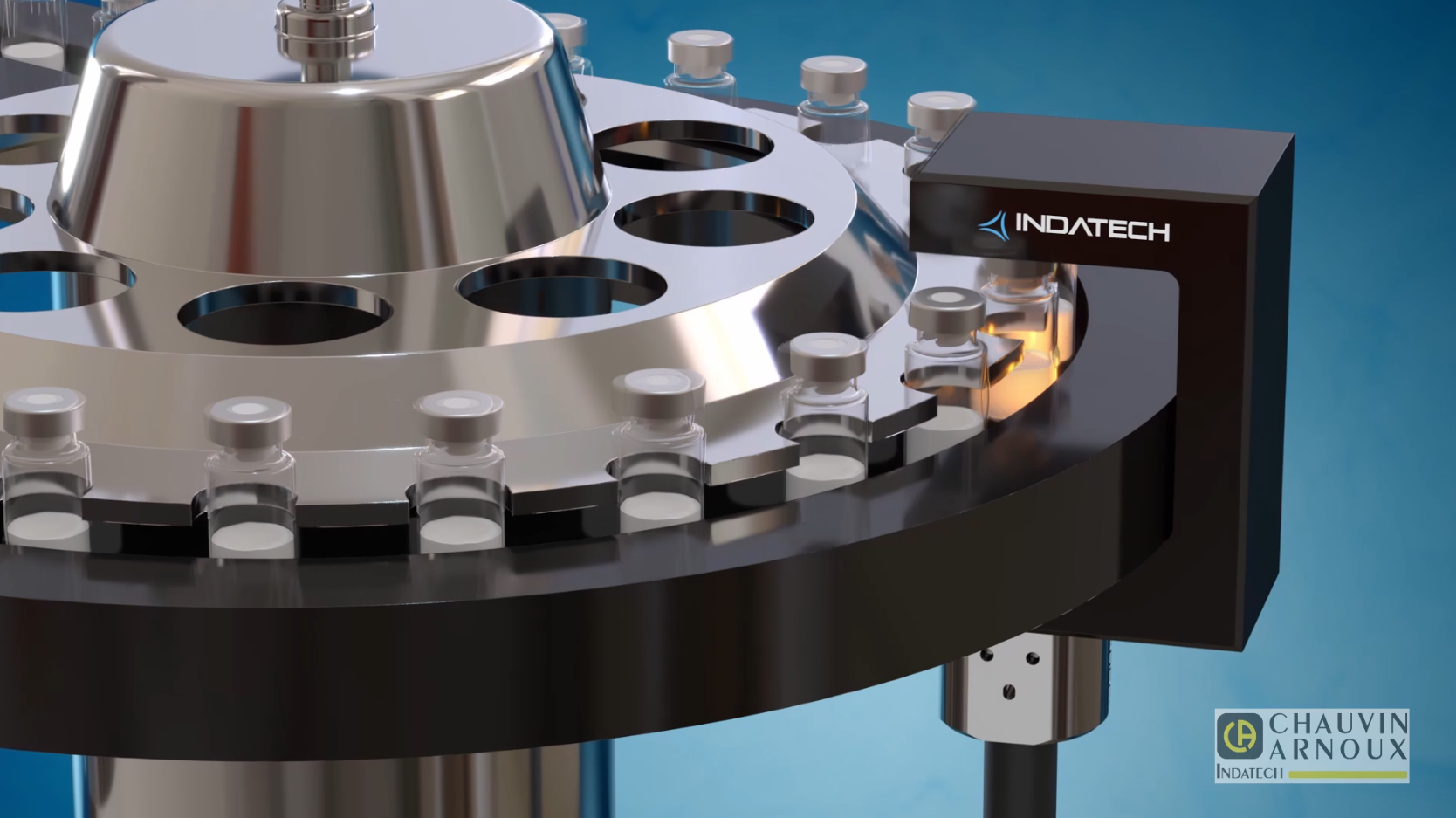

The SAM-Spec solution for analyzing lyocakes by means of NIR spectroscopy can be used to check moisture homogeneity and variability of the active ingredients.

Find out how to optimize your lyocake analyses with NIR spectroscopy!

Lyocake analysis by NIR spectroscopy can be used In both the development and production phases.

During production, SAM-Spec analyzes 100 % of the lyocakes. In this way, it significantly reduces the risks by checking the critical properties of each vial. Essential on continuous production lines, it allows direct control of the production facilities.

Benefit from a unique solution, as SAM-Spec uses patented technology.

SAM-Spec is the fruit of several years’ R&D work by INDATECH culminating in its innovative design combining the power of hyperspectral imaging (HSI) and the measurement accuracy of near-infrared Spatially Resolved Spectroscopy (NIR-SRS). This unique complementarity is ideal for analyzing physically and chemically dense products at high speed.

In this context, standard visible and near-infrared (NIR) spectroscopy is based on measurement of a single spectrum per sample, whereas Spatially Resolved Spectroscopy (SRS) takes simultaneous measurements at different distances from the lighting source.

Quick real-time measurement!

To maximize lyocake processing, choose a powerful analyzer capable of checking up to 100 times more products than a traditional approach.

In addition, as a multipoint measuring solution, SAM-Spec is capable of measuring up to 27 points simultaneously.

Watch the video

> To understand how our NIR spectroscopy solution works for lyocake analysis.

Parameters analyzed :

- residual moisture,

- homogeneity,

- hardness,

- contaminant detection,

- coating thickness, etc.

The advantages of our NIR spectroscopy solution:

- Multipoint: up to 27 simultaneous measurement points

- Exceptional measurement speed: less than 2 ms for 12 measurements

- Dual functionality: checks both physical and chemical properties

- Versatile system adaptable from the pilot study through to production